pine1,2,3,4 is for main rotation, connect nozzle in use.

pine5 is for vice rotation, used for injecting liquid or cooperating with main rotation.

Basic Specifications

1. Ultrasonic Frequency: 40KHz

2. Supply Voltage: AC220V ± 10% 50Hz

3. Input power: P <250W

4. Cleaning nozzle types: 500,126,128 ...

5. Control: Manual / Automatic

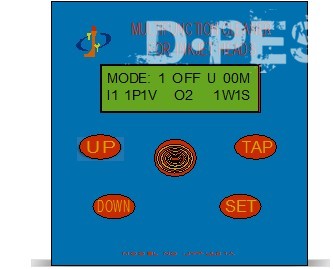

2、Operation panel

3、Function keys

(1) SET cursor

(2) TAP determine adjustments

(3) (this button is represented by“U”in the below) Ultrasonic control (start and adjust the duration, and other functions not related)

(4) UP lift up control

(5)DOWN lift down control

4、Display interface description

MODE:1 OFF U 00M

① ② ③

I1 1P1V O2 1W1S

④ ⑤ ⑥ ⑨ ⑦ ⑧

1. Adjustable type

Note: The following serial numbers correspond to the map ① ---- ⑨

① mode selection (from 1-4), adjustments will be off the circulatory system, but will not turn off the ultrasound.

② circulatory system switch (OFF / ON), ① ⑤ ⑥ ⑦ ⑧ ready to start. (Figure)

③ Ultrasonic working time (00-24), unit minutes, adjust the key corresponding to U.

⑤ pressure adjustment (1-2), 1-3 in the mode within the adjustable, in Mode 4 without this. 1 is a general pressure and 2 to increase the pressure.

⑥ pipeline adjustments (1-4), 1-3 in the mode within the adjustable, in Mode 4 without this. Then the pipe nozzle selection, four-channel selection from the left and right, example: a representative of a far left of the pipe, 3 represents the start of three from the left channel.

⑦ main working hours range from 1-9, in units of 10 seconds.

⑧ deputy working hours range from 1-9, in units of 10 seconds.

Note: (1) The following mentioned is the cleaning solution was to fight to the wash tank into the pipeline, pumping the contrary, from the wash tank out.

(2) main types of work for the first work, corresponding to the main working time, mainly in the mode 1,3, when the cycle inject. In mode 2, the main pumping cycle, the cycle mode 4 for the vice inject.

The type of work for the deputy work is, corresponding to the Deputy working hours, in the mode of 1,4-deputy pumping cycle. In mode 2 injecting of

Vice-loop. when in the main loop pumping in mode 3

(3) The main loop is cycle of the four pipe connecting sprinkler; the deputy loop is cycle of the single pipeline connecting the wash tank, mainly used to inject fluid or pumping fluid. They do not correspond to main or deputy type of work.

(Can not adjust the class, but can be changed automatically according to the system model)

④ the main type of work, showing, respectively: I1 (the main loop inject), O1 (the main loop pumping), I2 (Vice-cycle inject)

⑨ vice type of work, showing, respectively: O2 (the main loop inject), I2 (Vice-cycle inject), O1 (primary loop pumping)

5、Mode description

1. Mode type:

(1) When ① notes 1 as to Mode 1, the main loop inject, the Deputy circulation pumping, the first inject as the main cycle of rotation before Vice cycle pumping work, the main working time corresponding to the main loop inject, the Deputy Vice-cycle working time corresponding to pumping.

(2) when ① notes 2 as for the model 2, the main loop pumping, Vice loop inject. The first primary loop pumping cycle before injecting vice, as the work rotation, the main working time for the primary loop pumping, the Deputy Vice-cycle working time to inject the corresponding

(3) When ① notes 3a s a model f 3, the main loop inject before the main loop pumping, first inject berore the pumping work in rotation.The main working time corresponding to injecting, the Deputy working time corresponding to pumping

(4) When ① notes 4 as Mode 4, the Deputy cycle inject, Vice circulation pumping, first inject after the pumping work in rotation .The main working time corresponding to inject, the Deputy working time corresponding to pumping

2.Mode functions:

Mode 1, Mode 2 is used to clean spray, but only one-way. Model 3 for the two-way cleaning nozzle. Mode 4 is to inject fluid or extract of tank cleaning.

6.Operation Attentions

(1) steps: (1)transfer model → adjustment pressure →transfer piping→adjust the main time →

Vice-time transfer → start ( to adjust in the interface position ②)

(2) start the ultrasound (special keys U), has nothing to do with the other operations, may at any time, but the wash tank must have a 1 / 2 or more cleaning fluid.

(3) The keys of “UP and DOWN” control the lift, in the rise to the highest point and lowest point, the corresponding key is invalid

(4) The main and deputy working hours must be adjusted with the pressure and pipeline match. On the actual work, the type of main work cycle before the vice cycle, time to stop in ② is OFF.

(5) boot the default state is: ① 1, ② OFF, ③ 00, ④ I1, ⑤ 1P, ⑥ 1V,

⑦ 1W, ⑧ 1S, ⑨ O2

(6) The time to inject and extract: the main loop to inject about 50 / single, 40 / double seconds (to wash tank filling, until the washing tank 1 / 2)

The main loop pumping about 60 single, 40 / double seconds (pumping liquid from the wash tank, from 1 / 2 of wash tank to empty)

Vice-cycle inject about 80 seconds (to the wash tank filling, until the washing tank 1 / 2)

Vice-cycle pumping about 90 seconds (from the wash tank pumping liquid from the washing tank 1 / 2 to empty)

7. General Operation:

(1) to prepare a clean bottle of cleaning fluid, a waste bottle. (Note: The panel interface of two channels, one is for clean wash fluid, another is for fluid output connected to dirty water bottles. First cleaning nozzle pipe with mode 1, when the dirty liquids is pumped over basically, removed the bottle. Finally clean the both pines with wash cleaning liquid cycle)

(2) the appropriate choice of cleaning nozzle holder, nozzle and take a good external cleaning fluid and waste associated pipelines, according to a good power supply can be switched after.

(3) changes working mode, pressure, pipe number, the main working hours, the Deputy working hours (Note: If the nozzle is one just removed from the dirty machine, first use mode 1, may first be adjusted to: ① 1, ② OFF , ③ 00, ④ I1, ⑤ 1P, ⑥ 4V, ⑦ 1W, ⑧ 2S, ⑨ O2)

(4) start the cycle, that is ② switch “off” to “on”

(6) intermediate process of adjustment

(7) appropriate to start ultrasonic

(8) spray nozzle cleaning effect can be observed. (hoist nozzle holder, observed on mode 1,3)

(9) After finished washing, remove the nozzle, and turn off the power . If the nozzle is not clean, then continue cleaning.